The CIP-JET Function for Rotary Piston Pumps

What is the CIP JET Function?

The CIP JET function improves cleanliness inside the pump (portions in contact with liquid) during the clean-in-place (CI P) process. A sufficient amount of cleaning agent reaches inside the pump casing shafts, which are the most difficult parts to wash. This is why the CIP JET function alone cleans inside the pump without disassembling.

Prevents liquid from changing its characteristics caused by liquid buildup. The inside profile of the pump casing shafts (portions in contact with a liquid) is designed to avoid liquid buildup. This reduces liquid degradation.

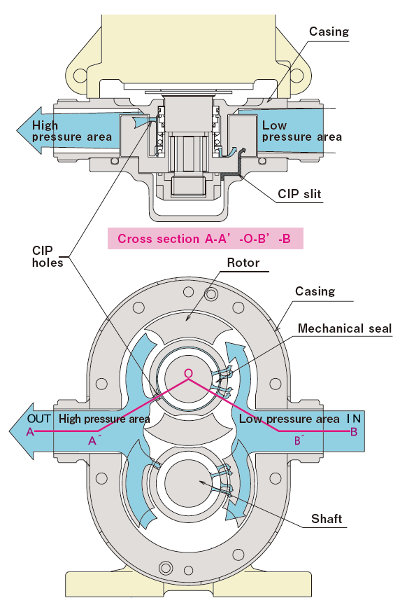

Operating Principle of the CIP-JET Function

The CIP JET function uses a pressure difference that exists between the inlet and outlet of the pump. Pumps with the CIP JET function have four CIP JET holes and slits.

Operation Sequence of the CIP-JET Function

|

1. The rotors of a pump equipped with the CIP JET function turn. 2. A pressure difference is generated between the inlet (low pressure area) and the outlet (high pressure area). 3. The liquid is pushed back from the high pressure area (outlet) to the low pressure area (inlet) through the CIP JET holes and slits. 4. The suction motion of the pump generates a force that extracts the liquid at the low pressure area. Repeating steps 1 to 4, continues high pressure liquid flow. |

![]()