Dope Solution at Chemical Plants

Liquid handled: Dope solution

Type of industry: Chemicals

Customer's Problems

The pump we have always used

· does not allow for idling.

· must be regularly overhauled, using a replacement machine in the meantime.

· The shaft seal uses gland packing, requiring regular retightening.

Nakakin’s Proposals

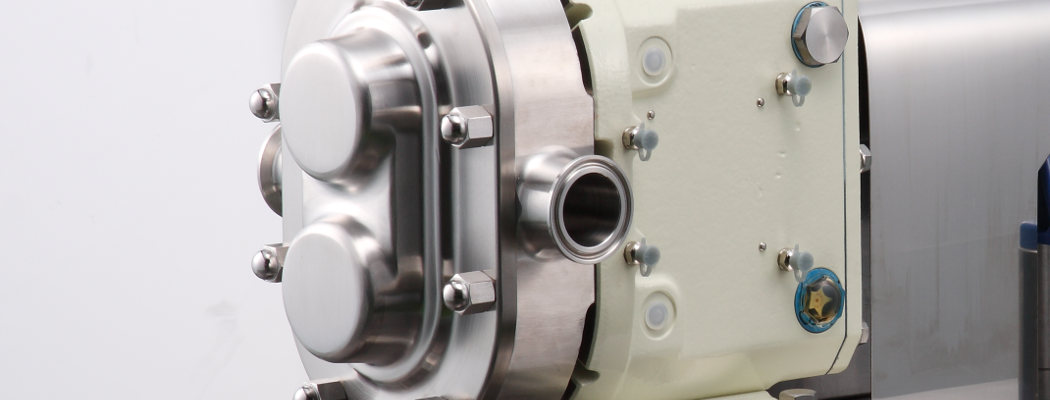

· We proposed using the Nakakin rotary piston pump JM Series.

· Using the Nakakin rotary piston pump allows for distribution of low- to high-viscous liquids.

· Due to the non-contact structure, there is very little risk of foreign object impurities.

· Due to the non-contact structure, there is no significant damage even after idling.

· Maintenance is basically unnecessary due to the use of a mechanical seal.

The Results

· Reduction in labor costs and time spent on maintenance!

· Greater peace of mind with regard to foreign object impurities and idling of the pumps!

![]()